Safe anti slip solutions

KJ Services offers anti-slip solutions for surface in your environment. We also help with installation and we are supported by experts who have used the product worldwide since 1983.

One third of these incidents are caused by slipping, stumbling, or falling. Not only do these incidents cause injury and pain, they also result in high costs. Loss of productivity, hospital expenses, and specific business expenses such as finding and paying for compensation on top of paid sick leave and additional HSE costs are all quite expensive. In addition, incidents often lead to poor reputation, significiant fines, or both.

Therefore, significant amounts can be saved by preventing these incidents from occurring by implementing the right safety measures. Research has shown that a sustainable reduction in the risk of workplace accidents is very profitable for both businesses and society as a whole. Sick leave decreases, the work atmosphere improves, and so does productivity.

As agent and distributor in Denmark of VIGIL®-products, KJ Services offers you our advanced solutions that solve the problem of slipping. VIGIL® is a prominent Australian brand that delivers professional anti-slip products worldwide, helping industrial environments, oil and gas industries, offshore environments, and in industry to increase their safety.

This sustainable material gets its superior quality and long life cycle from its specific manufacturing method, providing excellent long-term return on investment.

Falling down stairs often results in significant physical and traumatic consequences. Weather conditions or the presence of excessive amounts of oils, fats, and other pollutants increase the risk of incidents exponentially.

Vigil anti-slip stair coating (re) profiles the most important part of the steps by increasing the contact surface to protect against frequently occurring dangers caused by frequent use (polished step edges), worn or damaged stairs, and locations exposed to weather conditions or spilled liquids.

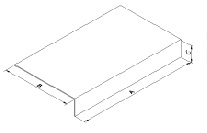

Stair nosings

90 degree angle

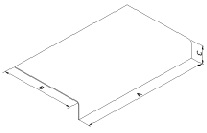

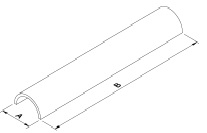

Bull nosings

8 mm (0,3”) radius

Standard size A – 450 mm, 600 mm, 750 mm, 900 mm, 1200 mm

Standard size B – 80 mm, 130 mm, 180 mm, 220 mm

Standard size C – 20 mm

Prices and sizes available upon request.

Standard characteristics: Commercial, industrial, offshore.

Vigil Anti-Slip Ladder Covers eliminate the risk of slipping from ladders by rebuilding and increasing the roughness of the step surface. In addition, they increase the friction coefficient and visibility.

Different weather conditions, clogging, and even thick or corrosive liquids do not in any way reduce the slip-resistant properties of ladder covers or the product’s life cycle.

Don’t expose people to the risk of slippery steps and use this unique product yourself or let our experts assist you.

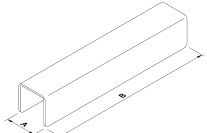

Square profile

Round profil

Standard sizes

A : 20 mm, 25 mm, 30 mm, 35 mm

B : 200 mm, 300 mm, 450 mm

Prices and sizes available upon request.

Standard characteristics: Light industrial.

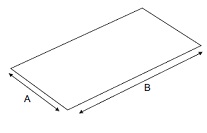

Surfaces that are or look even can be just as dangerous as stairs. Poor lighting, wear, unevenness and the presence of spilled liquids or exposure to other pollutants exponentially increase the chances of tripping, falling or slipping, resulting in injuries and loss of time and productivity.

Vigil metal deck removes the dangers of falling, slipping, and tripping. Furthermore, this product is highly resistant to mechanical stress, enabling, for example, forklift traffic, and can be used on a very wide range of surfaces such as concrete, uneven surfaces, and mesh flooring.

Standard sizes

A : 200 mm, 600 mm

B : 450 mm, 600 mm, 750 mm, 900 mm, 1200 mm

Prices and sizes available upon request.

Standard characteristics: Commercial, industrial, offshore.

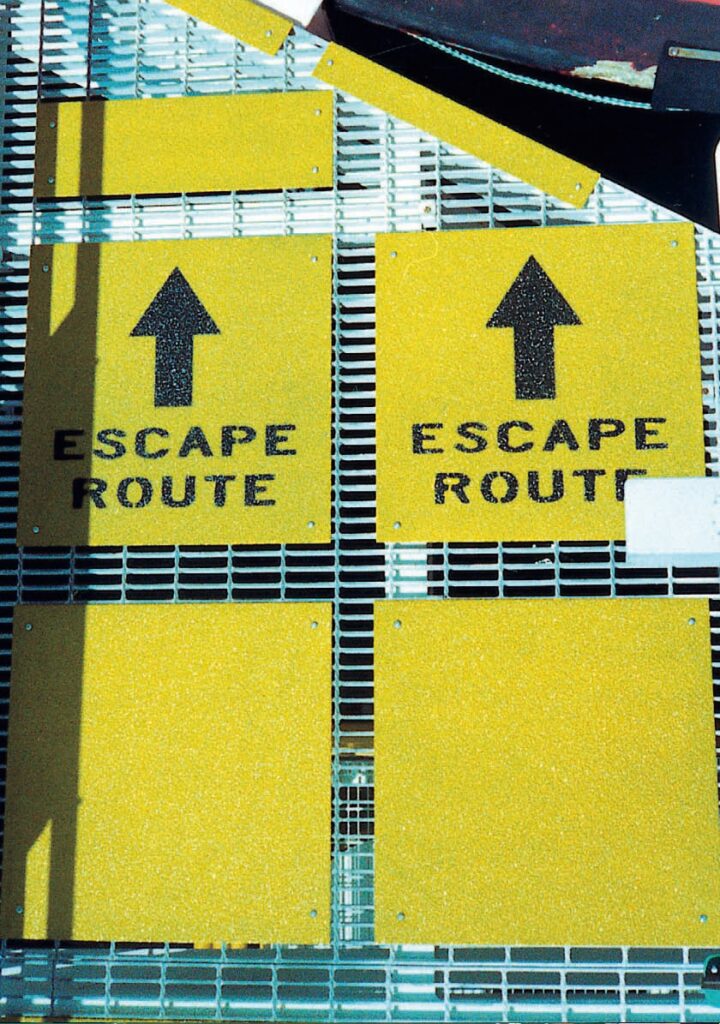

Vigil deck mark

Adding a deck mark to a slip-resistant product adds an extra dimension to the safety characteristics with Vigil anti slip. In any place where a quick and safe evacuation can save the lives of employees, Vigil anti-slip Deck Mark is an absolute necessity.

Each Vigil element can be equipped with a deck mark, indicating, for example, escape routes or other messages with internationally recognized symbols. The slip-resistant elements with the deck mark are placed exactly where people who escape a dangerous situation look: on the ground. The added symbols or texts of course do not affect the product characteristics in any way.

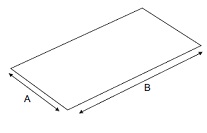

Vigil vinyl deck

A new floor made of cement, concrete, or vinyl may seem safe, but can cause just as much damage as an old, worn floor. Just leave some water or other liquid on it, and the dangers increase dramatically.

Vinyl deck is mainly suitable for curved or hollow surfaces (for example, tank trucks or silos) or surfaces with minimal mechanical stress. This product can be permanently applied to every surface with an adhesive. The material can easily be cut to size, and whether used in an industrial environment or in wet areas such as changing rooms or canteens, it does not discolor or delaminate.

Vigil Deck Light is a product family where a photoluminescent layer (self-illuminating in the dark) is integrated. Deck Light elements light up in the dark or when there is no lighting due to power failure. In an otherwise dark area, these elements light up and remain clearly visible for a long time. This makes Deck Light perfect for creating escape routes and walkways with guaranteed visibility and a rough anti-slip surface. Almost all Vigil products are available in Deck Light versions.

Deck Light is the ideal product for adding extra safety to escape routes when there is no light or when smoke appears.

– Made of high-quality material

– Afterglow time 8 to 12 hours

– No power, battery packs, or batteries required

– Easily used with mounting kit or screws

– Custom products available

Standard sizes

A : 200 mm, 600 mm

B : 450 mm, 600 mm, 750 mm, 900 mm, 1200 mm

Prices and sizes available upon request.

Standard characteristics: Commercial, industrial, offshore.

The guidelines below can be used for optimal installation of an anti-slip element on the desired surface. These are based on the most common situations/surfaces. If your situation/surface is different, please contact the sales department to receive custom advice.

Stairs & bull noses

For grated or perforated stair surfaces, the installation should be done with a mounting kit consisting of a hexagonal button head screw (M8x50mm), a saddle (mesh33), and a self-locking nut (M8). This assembly kit is available in either galvanized or stainless steel. The element should be drilled with a 9mm drill. The number of holes depends on the dimensions of the element. In case of a leveled concrete surface, the element can also be assembled using SIKAflex 291 adhesive.

Metal deck

If the situation is not or hardly mechanically stressed, it is sufficient to fasten with an adhesive kit. In situations that are regularly mechanically loaded, e.g. by forklifts or other heavy machinery, it is recommended to install with a recessed screw (M6) and a stud connection (diameter 7mm). In case of a metal surface (steel, aluminum, stainless steel, etc.), the anti-slip element can be installed using blind rivets (drilled diameter 4-5mm) or self-tapping screws (M6) or a recessed bolt and nut (pre-drilled diameter 7mm).

Ladder coverings

Fastening with SIKAflex 291A is sufficient.

Vinyl deck

In a situation with limited mechanical load using Vinyl decks, full surface bonding with a SIKAflex 291 adhesive is sufficient. This also applies to a curved or hollow surface such as a tanker truck.

In some situations, it is advised to combine the mechanical connection with an adhesive or set.

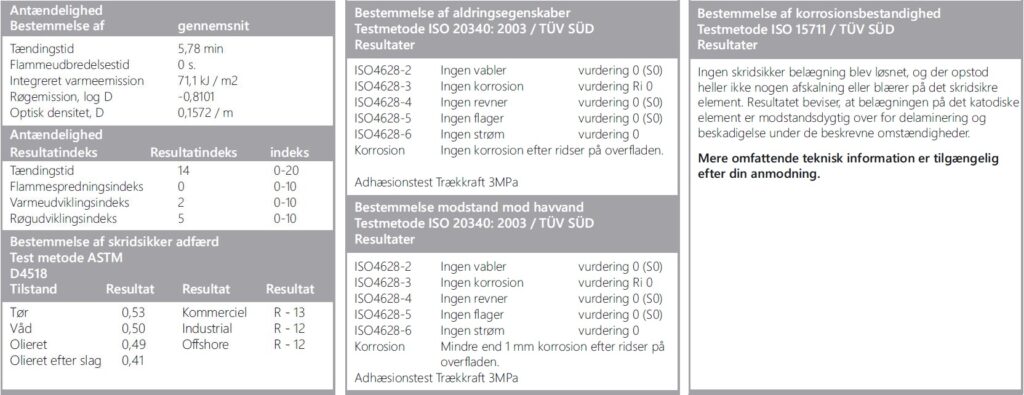

VIGIL® provides slip-resistant elements produced in a factory where environmental conditions are strictly controlled. This leads to a product with exceptional and consistent quality.

Experience has shown that flooring products used in workplaces are rarely applied under ideal conditions, due to time constraints and non-ideal conditions. After all, the floor needs to be returned to productivity as quickly as possible. Products whose quality varies by batch and the various types of surfaces they are attached to, which are almost never completely clean and grease-free when products are applied, have proven to be unusually difficult to apply a slip-resistant coating that proves to be sustainable in the future. Delamination (separation) of slip-resistant coatings can therefore hardly be prevented and leaves no alternative but expensive regular replacements.

VIGIL® offers two standard types of base surfaces for its slip-resistant metal products:

– A 1.2 mm thick Colorbond® metal element. Colorbond® is a metal equipped with a zinc/aluminum layer on both sides, on which a primer and yellow enamel paint are applied. This provides excellent resistance to corrosion, especially due to the self-repairing zinc layer. This solution is sufficient in most cases.

– If the material is exposed to seawater or a corrosive environment, 316 stainless steel with a 1.2 mm thickness is the most suitable base material. This 1.2 mm thick plate material creates sufficient rigidity to prevent delamination to the greatest extent, while it is limited and remains sufficiently thin to prevent any tripping hazards. Upon request, VIGIL® metal elements are also available with aluminum as the base material.

A flexible anti-delamination layer consisting of a special fabric is applied to the metal base of the element using special adhesives; an epoxy resin layer has been applied on top of this with the very hard silicon carbide slip-resistant layer on top. The product is then cured in a customized environment with a humidity of 0% and a surrounding temperature of 25 degrees Celsius. The manufacturing process ensures an optimal balance between slip resistance, moisture and good cleanliness in the workplace.

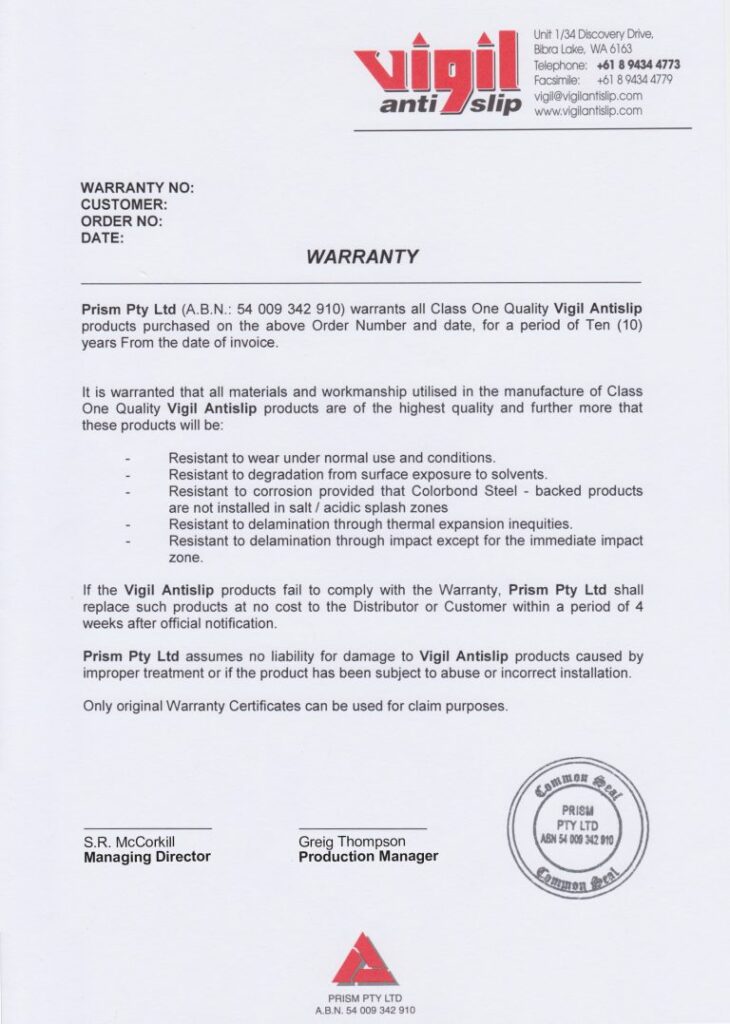

Delamination – separation of the coating layers – caused by the different layers’ different expansion coefficients and intensive use of slip-resistant layers, is one of the most significant challenges in creating sustainable materials. The flexible fabric layer applied to VIGIL® products in a highly controlled environment solved this problem. VIGIL® therefore offers a 10-year warranty on the risk of delamination!

When used in environments that are often dirty, the floors need to be cleaned regularly. VIGIL® material has excellent properties in these circumstances: they can be perfectly cleaned with scrubbing machines and high-pressure cleaners, even with hot water. The anti-delamination properties ensure that this product can be cleaned frequently and for a long time without problems occuring.

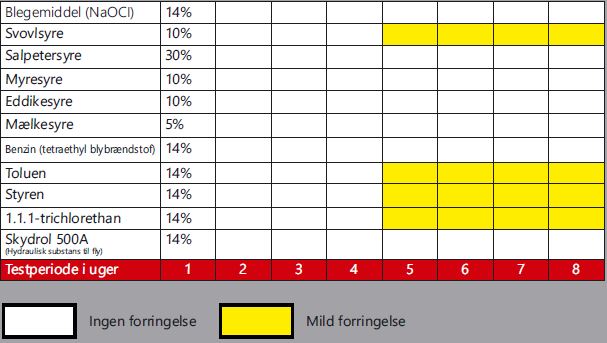

The slip-resistant coating is resistant to long-term exposure to most chemicals and especially solvents. The coating itself, of course, does not contain any solvents, otherwise common petrochemical products would deteriorate the surface.

The sustainable slip-resistant effect is achieved by using silicon carbide granules (SiC), also known as carborundum or artificial diamond. This is an unusually hard material used for purposes such as grinding, polishing, and diamond drill bit production. The hardness of any material is determined by its resistance to permanent mechanical deformation. The scale most commonly used to determine the hardness of materials is Mohs’ scale of mineral hardness. After diamond (with 10.0 Mohs), carborundum (with 9.2 to 9.5 Mohs) is the hardest material known. This provides a highly sustainable, abrasion-resistant slip-resistant coating.

Depending on the level of pollution associated with the work being performed on site, a roughness grade can be selected for the silicon carbide granules.

VIGIL® anti slip is offered in 3 qualities:

COMMERCIAL characters – Used in environments with limited pollution, such as warehouses, laboratories or canteens that require sustainable and solid slip-resistant conditions, the commercial quality is sufficient in almost all common situations. The combination of the best slip-resistant properties with proper cleaning ability, excellent chemical resistance, and high mechanical resistance makes VIGIL® a prominent product with an unusually long life cycle.

INDUSTRIAL characters – Industrial quality is used in work environments in production facilities and commercial spaces with medium levels of pollution. The silicon carbide granules used are less rough, making them harder in situations with medium levels of pollution.

OFFSHORE characters – In heavily polluted areas, often seen in offshore, oil, mud and mining, the Offshore quality is the standard choice. The structure with coarse silicon carbide granules ensures that the elements in these offshore quality elements still provide adequate slip protection even in heavily polluted areas before cleaning is required.

Stress resistance

Durability

Flammability

KJ-Services

Rahbeks Alle 11

DK – 6700 Esbjerg

Phone +45 23 32 93 50

Kim Jensen

Kim Jensen

Mobile: +45 23 32 93 50

E-mail: kj@KJ-Services.dk